Synchro-Smart™ Control and Communications Cabinet

The above ground cabinet houses the Synchro-Smart™ intelligent control system, the variable speed drive and the wireless communications module. The system on/off and operation parameters are set at the cabinet with LED’s displaying operation status. The sophisticated digital closed loop control system can be set to maintain constant dynamic fluid level or constant pump speed, detect pump-off conditions and monitor equipment performance. Synchro-Smart™ control achieves precise control by compensating for signal transmission degradation in the submersible cable. The wireless communications module supports web-based access to all well and pump operation data. Remote on/off and constant dynamic fluid level settings can be controlled through the web application.

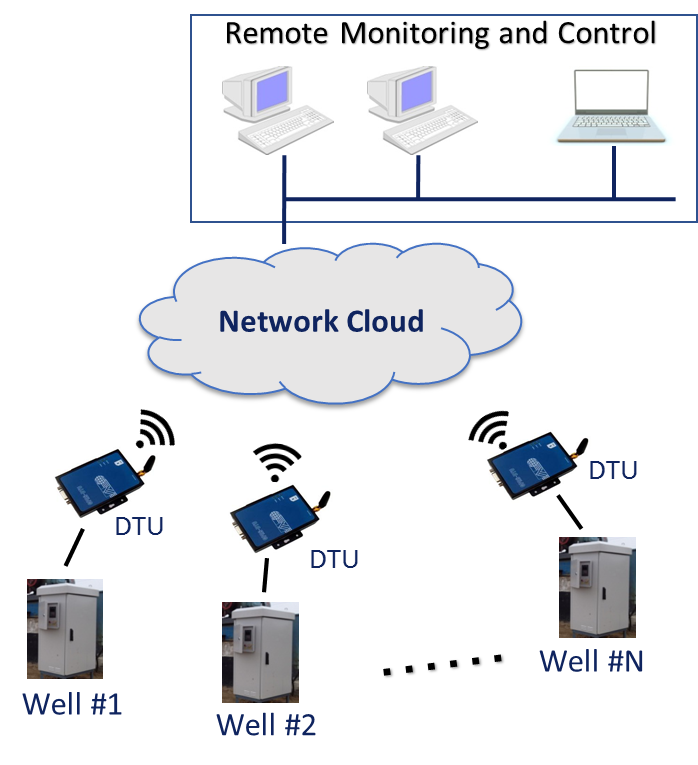

Communications

The wireless communications enables web-based access to all well and pump operation data and remote control of the Synchro-Smart™T System. Several digital transmission unit (DTU) modules are available based on available communication methods. DTU modules are available GPRS for 2G/3G cellular networks and satellite communications.

Variable Speed Drive

The variable speed drive controls the downhole Synchro-Smart™T system with advanced speed control utilizing high-frequency signal injection (HFSI). HFSI eliminates the need for mechanical speed or position feed back sensors and the inherent latency due to cable length.

Synchro-Smart™ Control

The Synchro-Smart™ Control system utilizes the well condition data from the downhole sensor in addition to the motor operation metrics to manage well fluid yield regulation. The control system can be set to operate in the following modes: dynamic fluid level management, manual selected pump speed and constant well fluid yield rate. In addition to managing well output, the control system maintains the Synchro-Smart™ Rodless Pump System preventing dry pumping and detecting signs of motor abnormal operations, transmitting alarms to connected remote terminals.

Continuous Real-time Well Monitoring and Decision Support

Central monitoring and control of all oil wells producing with Synchro-Smart™ pump systems supports well production maximization, scheduling pump maintenance and analyzing oilfield data for maximum recovery. The Synchro-Smart™ web portal provides easy access to an entire well portfolio. Real-time well conditions and pump operating parameters are displayed continuously and in the event of out of boundary conditions, the Synchro-Smart™ system sends alerts via text messaging, email and is visible on the monitoring screen. The Synchro-Smart™ retains historical data and includes graphing capabilities to analyze data trends of well conditions and pump operations.