Energy efficient artificial lift method with low environmental impact

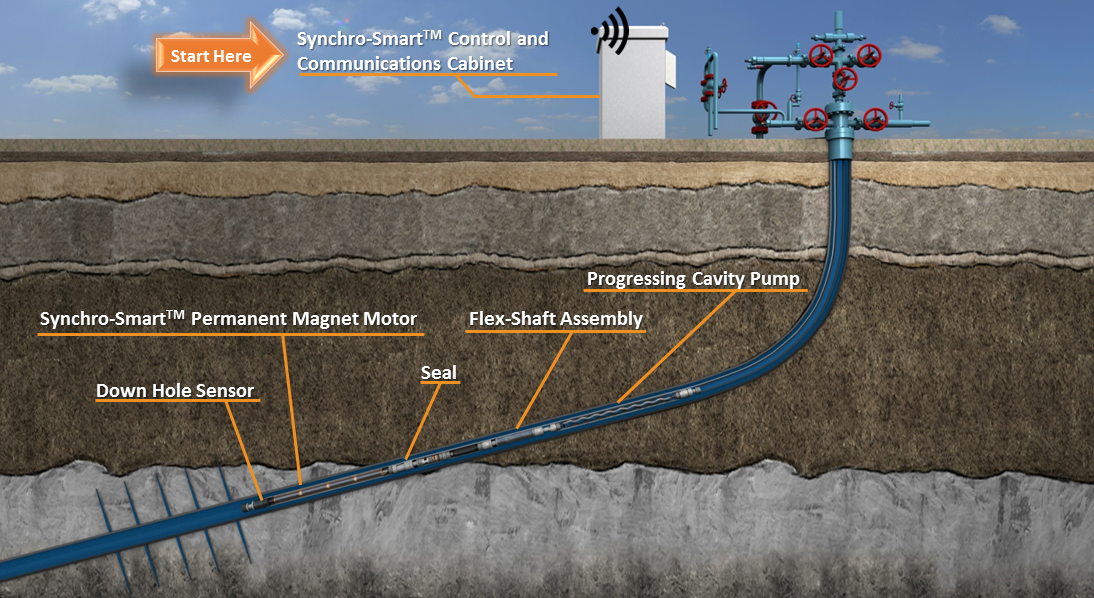

The Synchro-Smart™ Rodless PCP System is an intelligent system capable of dynamically selecting operational parameters to optimize production output. Driven by an electric submersible permanent magnet motor, the progressing cavity pump push up fluids at the maximum flow rate at the lowest pressure drop. The close proximity of the motor to the pump, and the continuous gentle pumping action and the synchronous permanent magnet motor result in lower energy usage and lower OPEX.

The Synchro-Smart™ System is beneficial in wells with heavy viscous oil, higher sand content, or higher gas content where ESP systems can be degraded. The submersible pump design alleviates mechanical wear from sucker rods and the production tubing in directional or horizontal wells. With a surface footprint of only 5 m2 the landscape is minimally affected and avoids the fluid leakage inherent to pump jacks.

Synchro-Smart™ Artificial Lift

Click on a component to learn more!

Synchro-Smart™ Control and Communications Cabinet

Synchro-Smart™ Control and Communications Cabinet

houses the Synchro-Smart™ intelligent control system, the variable speed drive and the wireless communications module. The digital closed loop control system can be set to maintain constant dynamic fluid level or constant pump speed, and monitor equipment performance.

Visit the Control and Communications Cabinet page to learn more!

Down Hole Sensor

Down Hole Sensor continuously measures well conditions including pressure, temperature, and vibration.

Visit the Down Hole Sensor page to learn more!

Synchro-Smart™ Permanent Magnet Motors

Synchro-Smart™ Permanent Magnet Motors range from 4 kW to 22 kW to efficiently drives the Synchro-Smart™Rodless PCP system.

Visit the Permanent Magnet Motors page to learn more!

Seal

Seal Section protects the motor from well fluid.

Flex-Shaft Assembly

Flex-Shaft Assembly couples the seal shaft and the pump rotor to compensate for the eccentric rotation of the pump rotor. The FSA also dampens the resulting vibration.

Progressing Cavity Pump

Progressing Cavity Pump gently moves fluid up very efficiently. Megmeet engineering selects the appropriate model based on fluid composition, pressure requirements, and well conditions. PCP’s are effective for lower flow rates, viscous oil, sand laden fluids and gassy wells. Additionally, they are appropriate when emulsion is a concern due to the low internal shear rates.

Visit the Progressing Cavity Pump page to learn more!